FE Exam – Aggregate Moisture States

For the FE exam or PE exam, before solving concrete mix design questions, we must understand the concept of how a mix design is largely dependent on the mass and volume of the aggregate particles. These aggerates with the binder must be proportioned in a way that will achieve desired concrete properties.

So how do we quantify the mass and volume of aggregates?

Density and specific gravity (or relative density) are used to quantify the mass and volume of a material. For concrete mix design, the specific gravity is more commonly used in practice.

\begin{equation}

G=\frac{\frac{\text { Mass Solid }}{\text { Volume }}}{\frac{\text { Mass Water }}{\text { Volume }}}

\end{equation}

Specific gravity of soil solids (pg. 259 FE Handbook 10.1)

\begin{equation}

G_{S}=\left(W_{S} / V_{S}\right) / \gamma_{W}

\end{equation}

Note: Most natural aggregates have particle densities between 150 and 181 lb/ft3 and specific gravities between 2.4 and 2.9.

So why are we talking about density and specific gravity? And what does that have to with anything related to the moisture condition of the aggregates?

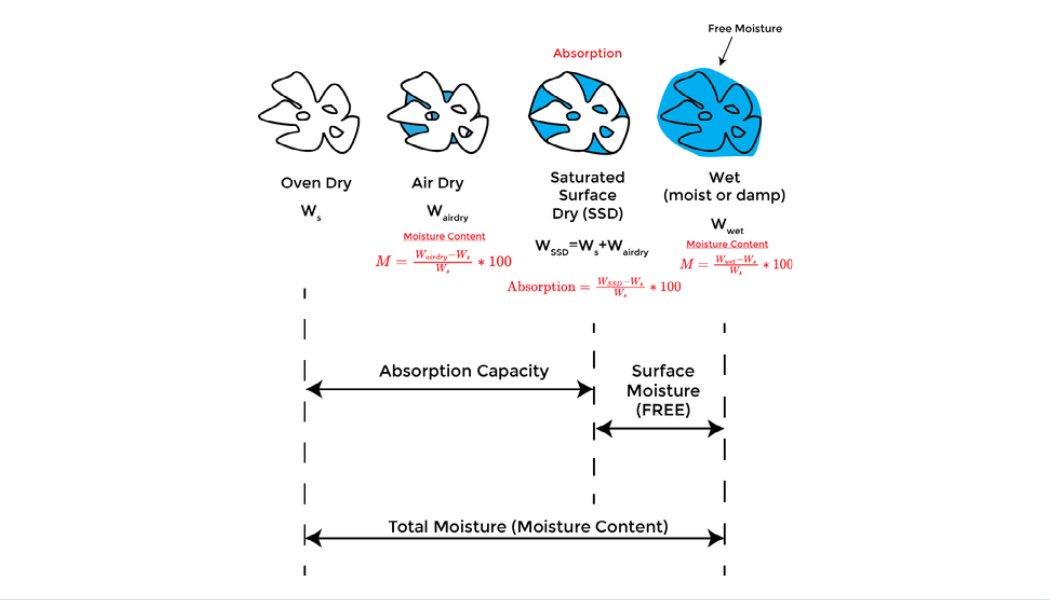

In summary, the density and specific gravity calculations we do must always consider the moisture condition of the aggregates. These calculations (while considering moisture condition) help us estimate the amount of moisture present the material supply we intend to use.

For example, in Portland cement, we may need to adjust the amount of water to maintain adequate water to cement ratio. Too much “free” water is bad since it would increase the water to cement ratio, consequently reducing the compressive strength. We should always aim to use aggregates in the saturated surface dry (SSD) condition.

Another example, in asphalt concrete, the aggregates will need to be dried to maintain the bond quality between the asphalt binder and aggregate particles. This is usually not a major concern for hot mixed asphalt (HMA) production since the aggregate is dried before production.

SSD stands for saturated surface-dry. This is the ideal moisture condition the aggregates must be brought producing a Portland cement concrete mixture. The surface is SSD when the substrate is saturated with water, filling the voids in the substrate’s aggregate, but the outer surface is devoid of free water.

The removal of free water from the surface prevents dilution and weakening of the product in exactly the location where strength is most vital: at the bond interface.

Know these moisture states by downloading and using the PDF below denoting the various moisture states with detailed calculations on how to calculate the moisture content for each state.

Aggregate-Moisture-StatesOven dry (OD)—no moisture on the surface of the aggregate, or permeable and impermeable pores.

Air-dry—no moisture on the surface; however, some of the permeable pores are partially filled with moisture. This is generally the condition of aggregate in storage.

Saturated surface dry (SSD)—there is no visible moisture on the surface of the aggregate and all the permeable pores in the aggregate are filled with water

Damp or wet—there is visible moisture (free surface moisture) on the surface of the aggregate and all permeable pores are filled with water.

Check out our Civil FE course where we walk you through the step-by-step procedure needed concrete mix design questions. We cover the concept of moisture states and reinforce our learning through plenty of examples.